|

||||

|

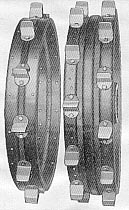

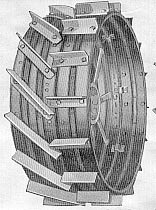

The steel wheels used on the Huber Light Four, 20-36 tractor have f1anged and grooved rims, heavy cast iron hubs and steel spokes hot riveted at hub and rim. Hubs are splined for rear axles and are held in place by heavy castellated nuts. Rear wheels are 50" in diameter with 12" face, front wheels 34" in diameter with 6" face. Wheel equipment consists of angle iron cleats 3" high or two bolt forged spade lugs either 4 1/2" or 6" high. There are 24 spade lugs or 16 cleats to each rear wheel.

|

|||

Fiber Pulley Pressed Fibre Belt Pulley. Belt will not slip. |

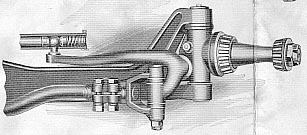

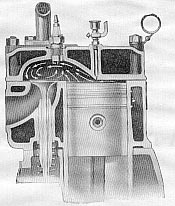

Ricardo Head Some of the outstanding advantages of the "Ricardo Head" are: more power, higher economy at all loads; quicker acceleration; freedom from "ping"; lower exhaust temperature that eliminates exhaust valve trouble; reduced crank case dilutlion; clean spark plugs; less carbon; less heating at all loads. |

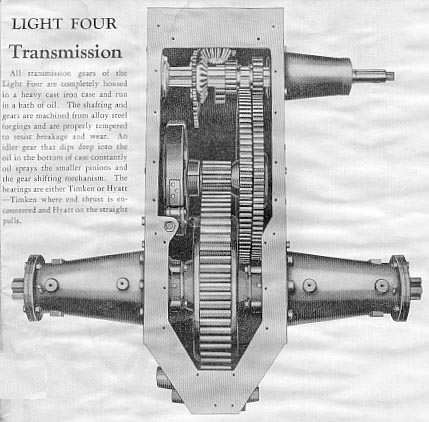

LIGHT FOUR

Transmission

All transmission gears of the Light Four are completely housed In a heavy

cast iron case and run in a bath of oil. The shafting and gears are machined from alloy steel forgings and are properly tempered to

resist breakage and wear. An idler gear that dips deep into the oil in the

bottom of case constantly oil sprays the smaller pinions and the gear

shifting mechanism. The bearings are either Timken or Hyatt - Timken

where end thrust is encountered and Hyatt on the straight pulls.

|

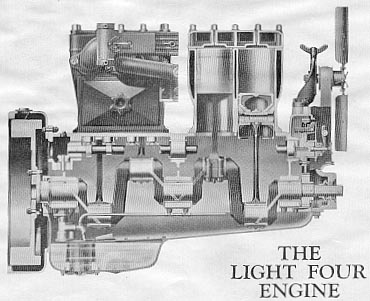

The heavy industrial type Waukesha engine with Patented "Ricardo Head" is the power plant of the Light Four. This engine was selected because it typifies the ideals behind the tractor as a whole - the desire and determination to make it absolutely the best in its class. |